The first recorded paintbrushes date back to 1330 A.D. during the times of the Phoenicians.

For centuries, paintbrushes remained round in shape. Even today, many European-made paintbrushes are round.

Here in North America, the majority of paintbrushes are flat in shape

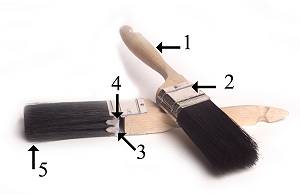

1) Handle - Can be made from wood, plastic or foam injection. Uniquely designed, the handle provides comfort and good balance. There are two ways to attach the handle to the ferrule; by nailing or crimping them.

2) Ferrule

- The metal band that holds the filament and the handle together is called

a ferrule. The ferrule can be made of bright tin, nickel, stainless steel,

copper or brass plated.

3) Spacer - The spacer is placed in the middle of the brush filament

to create a reservoir for the paint, and to maintain the filament tightly

in the brush.

4) Epoxy - Type of glue or cement used to lock the filaments permanently

into the brush.

5) Filament - Is the most important part of the paintbrush. Filaments

are made of natural hog bristle or synthetic materials.

Wood is the traditional standard for professional handles. Many contractors have preferred the balance, weight and feel of wooden handles.

The D.I.Y. quality of paintbrush handles are typically made of plastic or injected foam. The shape and style are dependant upon the intended job use.

Varnish - Pencil shape handles are designed for a comfortable feel when applying coatings on small to medium areas.

Wall - Large, thick handles allow a good, firm grip for painting large areas.

Various materials such as stainless steel. nickel, brass or tin are common alloys used. The importance of the material used is to assure rust and corrosion resistance.

Bristle : Natural pig or hog bristle is the most popular material used in paintbrush manufacturing. These bristles predominantly come from China. Bristles vary in length, stiffness and thickness. These natural characteristics are difficult to duplicate with synthetic materials.

Like some human hair, bristle has naturally split ends called "flags". Flags are very important. They help to hold paint in the brush so it is released evenly throughout the stroke instead of all at once on the first contact point. Flags also provide an extra-smooth finish with minimal brush marks because there are more "individual paint spreaders".

Nylon : When nylon was first used in the construction of paintbrushes, it was simply tapered filament mixed with horsehair. Over time, the processing of nylon has greatly improved so that now many contractors use nylon brushes. Because it is so durable, nylon is great to use on rough surfaces. Easy clean ability makes it the best material to use with fast-drying paints like acrylics.

Polyester : was introduced to reduce the cost of the synthetic filament. Also, the nature of the material does not allow the filaments to absorb any moisture whatsoever. It therefore maintains consistent stiffness.

Blends : The most popular synthetic paintbrushes combine the best qualities of nylon and polyester together in one brush. Polyester is used in the shorter

The first paint rollers were developed in England. Today, rollers are extremely popular. They are a fast, effective and simple method of applying paint to large areas.

1) Core - Base of the roller cover; it can be plastic, cardboard or phenolic-impregnated. Plastic cores vary in durability and quality levels, from DIY to professional.

Untreated cardboard cores are usually found in throwaway covers. Phenolic cores provide durability that stand up to many chemical products that are used for special applications.

2) Epoxy - Type of adhesive used to bond the fabric to the core of the roller; it resists solvents and chemicals.

3) Fabric - Part of the cover that carries the paint, consisting of individual fibres woven or knitted to a backing. Better roller covers have high-density fabric with many fibres per square inch as well as fibres of varying diameters, for higher paint capacity.

Roller covers, like brushes, are available in various qualities and can be made with natural or synthetic materials; 96% of all roller covers are synthetic.

Natural Fabric The original, natural roller fabric is shearling wool. Mohair covers contain blended natural and synthetic fibres. They have higher paint capacity than all other roller covers. Still, DIY painters rarely use these covers because they cost much more than synthetic ones.

Special use covers are designed for specific needs. Twisted fabric is used to create textured finishes.Polyurethane foam covers leave no lint and minimal air bubbles for glossy enamels. Synthetic, short napped fabrics apply adhesives and epoxies for wall coverings or floor tile. There is a roller cover designed for every type of application.

CHOOSING THE RIGHT ROLLER COVER

Many people only consider price when choosing a roller cover. There are many reasons why better-quality rollers are worth more than inexpensive ones.

Better Quality Roller Covers…

- Provides smoother coverage, fewer air bubbles and less lint on the surface. Denser fibres reduce spattering and even release layoff from the beginning to the end of the stroke.

- Holds more paint per dip (have higher paint capacity) Saves time!

- Lasts longer. Higher quality materials resist matting and are more durable.

- Recommended

Fabric Pile Heights for Specific Surfaces :

Smooth 3/16"-1/4" (5mm-6mm)

Semi-Smooth 3/8"-9/16" (10mm-15mm)

Semi-Rough 3/4" (19mm)

Rough 1" (25mm) and over